Home » Pasco wheelchair manufacturer earns key ISO certification

Pasco wheelchair manufacturer earns key ISO certification

October 14, 2020

They already knew it was true, but now, everyone else will too.

TiLite, a custom wheelchair manufacturing unit of Permobil, has been a fixture in the Pasco community for about 20 years.

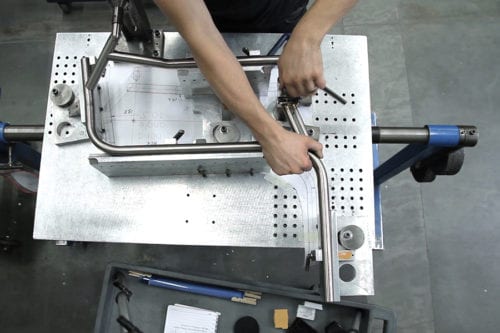

It has been creating innovative, aluminum and titanium wheelchairs while meeting the high standards of the FDA.

Now, after months of overhauling its systems, TiLite has earned the International Organization for Standards’ industry-leading ISO certification for medical devices and related services.

ISO certification is proof Permobil and TiLite are dedicated to creating wheelchairs of the highest quality.

TiLite has spent the past 18 months undergoing an extensive process of adapting its operation to earn this certification. Specifically, ISO 13485 designation for “organizations involved in the design, production, installation and servicing of medical devices and related services,” according to the ISO website.

Brad Wolfe, regulatory manager and project leader at TiLite, sees it as further proof of what he already knew, that TiLite has a good manufacturing system that can be repeated, that its products do what it says they will.

“That shows all the other countries and the FDA ... that we can, time after time, produce a safe product,” he said.

Not just any company can proudly wear the title of an ISO certification.

The U.S. Food and Drug Administration announced in 2019 that it plans to update its Quality Systems Regulation, or QSR, for medical devices to meet the standards of ISO 13485 for audit inspections.

Chuck Witkowski, president of Permobil Americas, confirms the dedication Permobil has always had when it comes to carrying out its mission to help people achieve the greatest level of independence they can through its products.

“I think that the certification itself is a great achievement, but really I think that it’s what it stands for that is important,” he said. “And for us that means a focus on quality, whether it’s from the design phase through manufacturing, but I also think it speaks to who we are and who we want to be in terms of quality.”

It makes sense they would want to highlight their commitment to settling for nothing short of perfection. TiLite wheelchairs and other products go beyond assisting people in their everyday lives. Wheelchairs serve as an extension of a person’s body.

The 230 members of the Permobil team find it immensely rewarding.

“I love it here. It’s one of those jobs and one of those companies where you can really be proud of the products you create, and the difference in people’s lives that you make. Definitely not everyone can say that,” said Caleb Gilmour, production manager, who has been working at TiLite for about five years.

Gilmour has lived in the Tri-Cities his whole life, living just across the highway from where he grew up. He has memories of going into a Pasco grocery store when he was younger. That building is now the manufacturing center where he is production manager.

“This community has supported me my entire life, so it’s just one of the ways I can give back and pay it forward. But I’ve got the best team here. They all mean as much to me as my own family,” he said.

That’s not going to change anytime soon.

“We’ve been part of the community for quite some time and we intend to be, going forward,” Witkowski said.

TiLite began building bike frames, golf shafts and other athletic equipment with titanium and shifted to performance wheelchairs in the late 1990s. Permobil, a global wheelchair firm based in Sweden, bought it in September 2014. The international company employs 1,600 people in more than 15 countries.

The hard work the TiLite family does each day was featured on actor John Ratzenberger’s show promoting U.S.-made products, “Made in America,” in 2009. The profile is posted at bit.ly/PermobilMadeInAmerica.

When watching the TiLite team in action, it’s apparent how dedicated to excellence the staff is — and now they have the certification to prove it.

Business Profiles Local News

KEYWORDS october 2020