Home » Kennewick company looks to create new source of green energy

Kennewick company looks to create new source of green energy

June 15, 2016

When it comes to hydroelectric power, most people think of a mighty river and a massive dam. Electricity is generated when the build up of water is released from the reservoir. The energy of water falling over the dam is then converted into electric energy through a turbine.

There are about 2,500 hydroelectric plants in the United States, and most have elevation drops where the water falls from 50 to more than 300 feet. But Jerry Straalsund, president of Percheron Power in Kennewick, set his company’s sights on something smaller.

“There are a lot of places where there’s small drops of less than 30 feet. You have to handle of lot of water to get power, but we were interested in finding the best technologies to make these smaller projects viable. Irrigation canals are usually pretty flat for a while. They are designed so that the water doesn’t flow too fast. Then there will be engineered drops often to 30 feet or so to accommodate the terrain change, and that’s what we’re looking at,” Straalsund said.

In order to be successful at harnessing power from small drops, Straalsund and his team needed to improve on the Archimedes Hydrodynamic Screw Turbine already being used in Europe. While efficient at collecting energy from areas like canals, the European technology is expensive, especially if it needs to be shipped to the United States.

Percheron Power came up with a solution to make the turbines out of composite material instead of metal, and reached out to Pacific Northwest National Laboratory (PNNL) and its Technology Assistance Program.

For more than two decades, PNNL has offered qualifying companies support with about a staff-week worth of technological assistance. Since the program’s inception, Gary Spanner, PNNL’s manager of economic development, said PNNL has helped with more than 1,300 projects.

“We’ve done projects such as energy-balance calculations, biofuels process development and a lot of materials characterization,” Spanner said. “For Percheron, we developed some prototype turbine blades.”

Shortly after participating in the Technology Assistance Program, Percheron Power learned PNNL—along with the Department of Energy (DOE) and all of its labs—was going to kick off a Small Business Vouchers pilot to further the support of businesses.

“What the technology assistance did was give companies a window into PNNL’s capabilities and what we can do for them. The lab directors wanted to do something more impactful,” Spanner said. “So we laid out the principles of the Small Business Voucher pilot. Energy efficiency is fundamental to the pilot.”

Funded by DOE, PNNL is one of five labs comprising the pilot’s leadership team. Spanner said DOE has allocated $20 million dollars in support over three rounds, with each voucher as much as $300,000. Percheron Power was one of about 400 companies that requested funding in the first round, and project development director Sharon Atkin said they were thrilled to be awarded $200,000 in support.

“We were the only business in Washington State to be selected for the federal pilot,” she said. “The pilot was targeted at the clean energy sector, and we were only one of three awards in the country that was focused on hydropower.”

The selection couldn’t have come at a better time. Atkin said Percheron Power had been trying to find a way to secure funding to get a composite of the European turbine created. This spring, the company began working with PNNL engineer Marshall Richmond, who is the research lead for the project. A small sample of Richmond’s areas of expertise include the development and application of computational models of hydrodynamics, computational fluid dynamics and physical modeling of hydraulic structures.

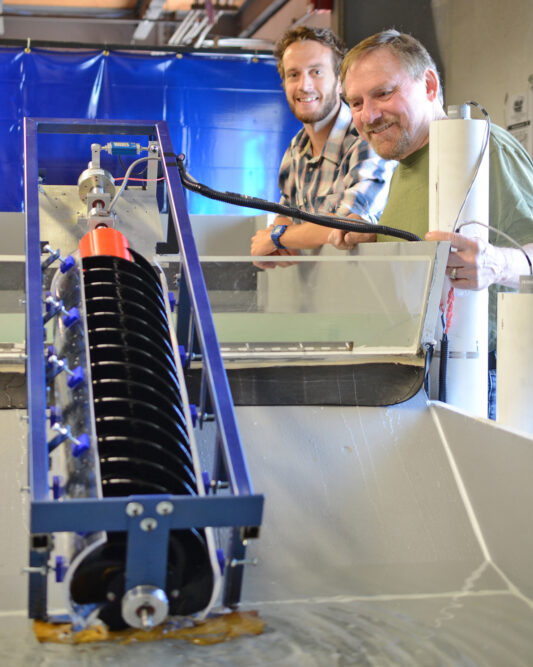

With Richmond’s help, Percheron Power has created a mini model—an eight-inch diameter turbine—to laboratory test.

“We’re going to water test it, and we’re expecting to be able to have the results in about six weeks,” Straalsund said.

“And then we’ll move to the next size up,” added Atkin. “PNNL will be modeling that, and they’ll help us make choices on how to best optimize the designs from the model.”

The six-foot model for phase two will be installed at the Utah Water Research Lab, Atkin said. Percheron Power will take several designs with them, and once phase two testing is complete, Straalsund said they’ll put a composite turbine in a long-term position.

“That’s about two years from now,” Atkin said. “That will go to a permanent field test. We’ve looked at places between here and Yakima, and we’ve had a lot of interest from a prominent town in Colorado that has pursued us to do a field test there.”

There are no Archimedes Hydrodynamic Screw Turbine plants operational yet in the United States, but more than 10 applications have been submitted to Federal Energy Regulation Commission for sites in California and Washington, said Atkin, adding that steel turbines must still be imported for these sites, which makes it hard for many plants to afford them.

When all is said and done, Atkin believes their product will be 40 percent lighter and more efficient than the European version and will produce clean, renewable energy with much lower impact than traditional hydroelectric dams.

“The idea is to have distributed green renewable energy sources instead of having big coal plants—make the grid more efficient,” Atkin said. “And this is ultralow environmental impact. For hydro—with the salmon and other impacts—everyone’s being very careful. It’s important that any hydro we do is ultralow impact now, and that’s what’s especially great about this technology.”

Local News Energy

KEYWORDS june 2016