Home » Scientists pioneer renewable energy pathways for jet fuel

Scientists pioneer renewable energy pathways for jet fuel

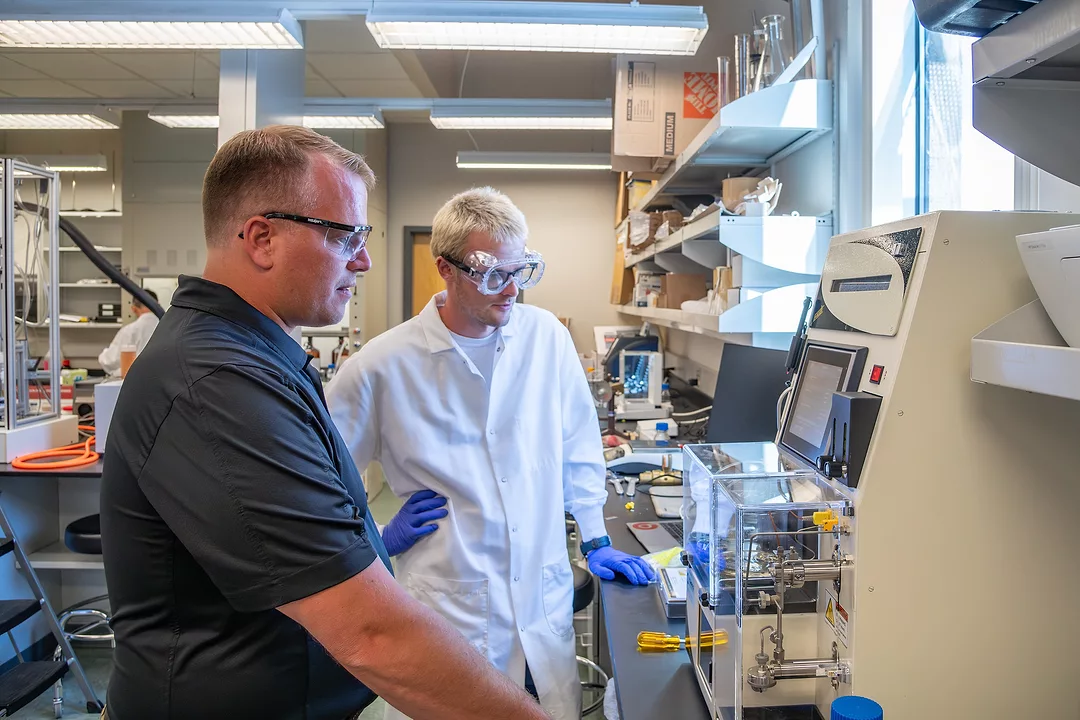

Joshua Heyne, director of the Bioproducts, Sciences, and Engineering Lab (BSEL) and co-director of the WSU-PNNL Bioproducts Institute (BIO-IN), left, and Conor Faulhaber, graduate research assistant, Alaska Airlines fellow, and Distinguished Graduate Research Fellow Program (DGRP) recipient, read a Jet Fuel Thermal Oxidative Test result. The test is important to ensure that SAF operates equivalent or better than conventional fuels.

Courtesy WSU Tri-CitiesDecember 14, 2023

Researchers are working to convert everything from cooking oil to sewage waste into sustainable energy sources that can fuel airplanes and provide energy for communities.

Washington State University Tri-Cities scientists are at the forefront of pioneering ways to reduce fossil fuel use by developing and testing ways to make renewable energy out of waste or materials we already have in our backyard. From livestock manure to sewage waste to used cooking oil and tallow, energy can be extracted through various resources, given the right biological processing.

Clean energy is more vital than ever. In 2021, net emissions increased in the United States by 6% as post-Covid activity rebounded, and nearly a third of those emissions are due to transportation sources, like vehicles, trucks and airplanes, according to the Environmental Protection Agency.

From 1990 to 2021, transportation carbon dioxide emissions from fossil fuel combustion increased by 19% in the U.S., and while most of those emissions are from vehicles, planes are also responsible for carbon dioxide emissions via jet fuel.

And while airplane emissions make up just 2.5% of total global carbon dioxide emissions in 2018, the work to convert existing waste into sustainable aviation fuel remains ripe for discovery, which is where the WSU Tri-Cities researchers come in.

They are trying to find ways to efficiently create sustainable aviation fuel, called SAF for short.

On Nov. 28, the first transatlantic flight using SAF took off from London and landed in New York, the Guardian reported. The Virgin Atlantic flight used fuel produced from tallow and waste, the Guardian reported. It’s the first flight to use 100% SAF.

Currently, some airlines use SAF to partially fuel their planes.

Joshua HeyneJoshua Heyne leads work around finding materials and processes for developing SAF as the director of the WSU Bioproducts, Science and Engineering Laboratory (BSEL) in partnership with Pacific Northwest National Laboratory.

Joshua HeyneJoshua Heyne leads work around finding materials and processes for developing SAF as the director of the WSU Bioproducts, Science and Engineering Laboratory (BSEL) in partnership with Pacific Northwest National Laboratory.

His team works with about three dozen companies across North America and Europe to take materials (both purposely grown as well as natural waste), capture the carbon dioxide and then convert it into SAF.

The aviation industry is working toward fueling planes with “100% SAF,” Heyne said, as a way to “minimize the impact aviation has on human health and the environment.”

To make 100% SAF, the process needs to be “backwards compatible” or not contributing to emissions in the process of trying to renew the energy. To achieve this, researchers are looking at how to locally source both the supply and the transportation of SAF. Heyne said that to minimize emissions, SAF production should be as local as possible.

Finding the silver bullet

In Washington state, there are three facilities that currently produce SAF, which Heyne said will not meet the eventual SAF fuel production need (in proportion to consumption) statewide.

In the meantime, researchers continue to look for additional pathways to create SAF. One pathway, from ethanol to jet fuel, which was developed at BSEL is now being implemented at a commercial plant in Georgia, Heyne said, with more facilities likely to come online in the future.

The research must continue, however, for new materials to create SAF, as the current methods and materials are not enough to produce what’s needed.

Ultimately, testing new materials is the way to find new pathways.

“There is no silver bullet right now, in terms of being able to do things at scale and at price parity,” Heyne said.

That doesn’t mean SAF is irrelevant, however. If you fly out of LAX, for example, there’s a chance your plane is using some SAF. In the future, airports might incentivize using the more sustainable jet fuel at their hubs, Heyne said.

The BSEL team is also partnering with Snohomish County and the Paine Field Airport in Everett to develop a way to do larger scale tests. In April, officials announced plans for a $6.5 million research center.

Walla Walla sewage sludge

Birgitte Ahring, a professor who leads the BioScience and Technology Group at BSEL, is a part of the team that published research last year showing the results of a pretreatment process on sewage sludge that they performed in Walla Walla. Ahring and her colleagues found that 84% of the organics in sewage sludge could be transformed to biogas if the material underwent a specific pretreatment process.

Birgitte Ahring

Birgitte AhringBut with a new pretreatment process, the facility could capture upwards of 80% of the material and convert it to biogas, resulting in less waste sent to landfills and the majority of the waste being converted into renewable energy.

Ahring is confident in their pretreatment process, which is currently being scaled up in Europe, she said.

Renewable natural gas can be used for chemical production, to produce SAF, or simply natural gas that can be put out on the grid, although storing and transporting it can be tricky and depends on where the wastewater treatment facility or landfill is located and whether they have a way to release that gas onto the grid.

Ahring and her colleagues also are studying how to use food waste to create renewable energy, instead of causing emissions to increase as they decompose in landfills. Researchers are also studying lignin, the polymers in plants like wood and bark, for how they can be processed into SAF, Heyne said.

Ultimately, the hope is that waste can easily and affordably become the start of a new energy cycle, and the goal, Ahring said, is to create a “circular economy.”

When the majority of sewage sludge is converted back into biogas as renewable energy, the circle is complete, with a resource being used and then its waste being reused to create energy.

Without it, the circle is broken, Ahring said.

Education & Training Energy Environment

KEYWORDS December 2023

Related Articles