Home » 3D printing pioneer to speak at fundraising brunch

3D printing pioneer to speak at fundraising brunch

Point to Success is Feb. 3 to benefit Carson College of Business at WSU Tri-Cities

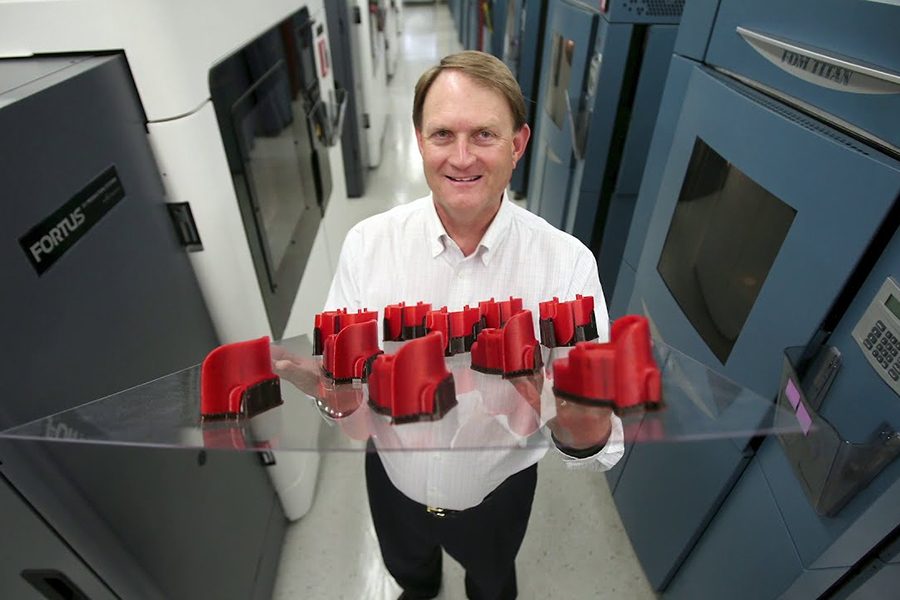

Scott Crump, the inventor of fused deposition modeling, is the featured speaker at this year’s Point to Success brunch on Feb. 3 to benefit the Carson College of Business at WSU Tri-Cities.

Courtesy Scott CrumpJanuary 12, 2024

A toy frog made from a hot glue gun inspired an inventor to blaze the trail of 3D printing, and a friendship formed at Washington State University brings him to the Tri-Cities this February.

Scott Crump, inventor of fused deposition modeling and founder of Stratasys, will be the featured speaker at this year’s Point to Success brunch on Feb. 3 to benefit the Carson College of Business at WSU Tri-Cities.

Born in California, Crump grew up in Connecticut and got his start as a student at Washington State University.

By the end of high school, Crump knew he was interested in mechanical engineering. He believed WSU was the best school for undergraduates to study hands-on, not theoretical, aspects of the field.

During his time at WSU, from 1971-76, Crump visited the Tri-Cities once or twice. Though he spent much of his time studying, he enjoyed the social life of the Delta Sigma Phi fraternity and Pullman’s easy access to the country.

“Most of my friends liked the outdoors,” Crump said. “So we’d go fishing up north or we would go deer hunting or bird hunting, like pheasant hunting, in the area.”

He also met Gary Spanner, a fellow mechanical engineering student. The two took some of the same classes and became friends. Spanner, of Pasco, retired as economic development manager for the Pacific Northwest National Laboratory in Richland.

Spanner has helped with fundraising for WSU and called Crump about presenting both to the mechanical engineering school at WSU in Pullman and the Carson College of Business Point to Success brunch in the Tri-Cities. This will be the first time Crump has spoken at a fundraising event.

Beginnings of business

After leaving WSU, Crump stayed in the Northwest, taking a job at Fluid Air Components Inc. in Portland, Oregon, where he helped cut logs and boards with high precision hydraulic technology.

Five years later, he went back to school, this time for entrepreneurship. At UCLA’s Anderson School, he learned about fundraising, sales and marketing from the CEOs and vice presidents of local companies.

That was the launchpad he needed to start a company of his own.

Crump’s first business was selling plans for log splitters. Recently out of school, he had little money to sell the log splitters themselves, but he quickly broke even selling the plans.

He then co-founded Idea Incorporated in California, a company making markers for semiconductors. The company printed markings on top of semiconductor chips and forced the early failure of chips to ensure overall quality.

While working there, he noticed a boom-and-bust cycle in the microchip industry caused by the length of time it took to develop prototypes. While there were successes, the down time was often disappointing and could include layoffs.

Crump, “figured that if we could accelerate the prototyping process, we wouldn’t have to go through a down cycle.”

This was the spark that led to Crump’s 3D printing innovation. The ability to take an online design and print it as a 3D model would decrease the time it took to prototype products, reducing the down time.

FDM and Stratasys

One day, Crump sat down with a hot glue gun to make a couple of toys for his daughters. He laid down one layer of glue at a time and found that the layers would bond, enabling him to make a shape.

“It’s kind of like sculpting, or chiseling in reverse, where you’re building it up,” Crump said.

His daughter played with the toy frog he had made, and Crump went to the garage to start testing the possibilities of precision layering. Today, his method of 3D printing is known as fused deposition modeling, or FDM.

The method works like the hot glue gun: the building material, called the filament, goes into the head of the 3D printer, which moves like a pen to put down a line of filament. The layers slowly build up, creating the object.

There are other methods of 3D printing. Stereolithography or SLA, for example, involves a vat of liquid which can be solidified by using the right laser. But 90% of 3D printers use Crump’s technology.

Connected to a computer design program, like AutoCAD, 3D printing would work just like 2D printing. The print pen “would move one point to another, automatically building the shape … you could build pretty much any shape that you could draw,” Crump said.

Seven prototypes after his first experiments, Crump and his wife, Lisa Crump, launched Stratasys. The company had a slow start as Crump learned how to draft a patent and lobbied for investors to get the company off the ground. Crump and his wife were told numerous times that it was crazy to take this risk – but it paid off.

“We had sold everything we had, except for our wedding rings, to get the thing going,” he recalled.

They struggled to raise enough funds through private investors, and finally reached a turning point: the company could either close or go public. So, the Crumps opened it up.

A global company

With a public company, the Crumps managed to raise $30 million, far above the $90,000 Crump initially thought it would take to break even. Stratasys’ success led to a merger with a 3D printing company in Israel, work with JP Morgan and $600 million in revenue with products offered in 71 countries.

Crump’s first patent was successful, and today he owns more than 20.

For Crump, “a clearly thought-out business plan,” especially one taking finances into account, is key to starting a new business. The plan, the persistence to execute it and a willingness to raise money are all factors in a company’s success.

But it’s also important to “take the biggest risk that you can possibly stomach… The only way you can grow a company is by taking a risk,” according to Crump.

After being the CEO and chairman of Stratasys for 25 years, Crump took the opportunity to step down from his CEO role after the merger with the Israeli company, Objet Geometries LLC. Today, he is no longer the chairman but is still on the board, and travels all over the world for board meetings.

Crump enjoys the travel. Though he lives in Minnesota now, where Stratasys is located, he spends 20% of his time traveling. In the past year, he’s been to Kenya, Ethiopia and Israel, and his upcoming talk at the Carson College Point to Success brunch in Richland will be just one stop on a Pacific Northwest trip to include time in Seattle, Pullman, Portland and Bend.

Crump is looking forward to speaking at the brunch and visiting friends in the Tri-Cities, including Spanner, his former classmate.

Event registration

The Point to Success brunch is from 9:30 a.m. to 1 p.m. Feb. 3 at Anthony’s at Columbia Point, 550 Columbia Point Drive in Richland. Cost is $150 per person, or $500 for a table of four, and it includes games, brunch and a live auction. Go to: bit.ly/2024PTS.

Latest News Architecture & Engineering Entrepreneur Startup Ecosystems

KEYWORDS January 2024

Related Articles