Home » Region’s largest commercial corn flaker coming to Plymouth

Region’s largest commercial corn flaker coming to Plymouth

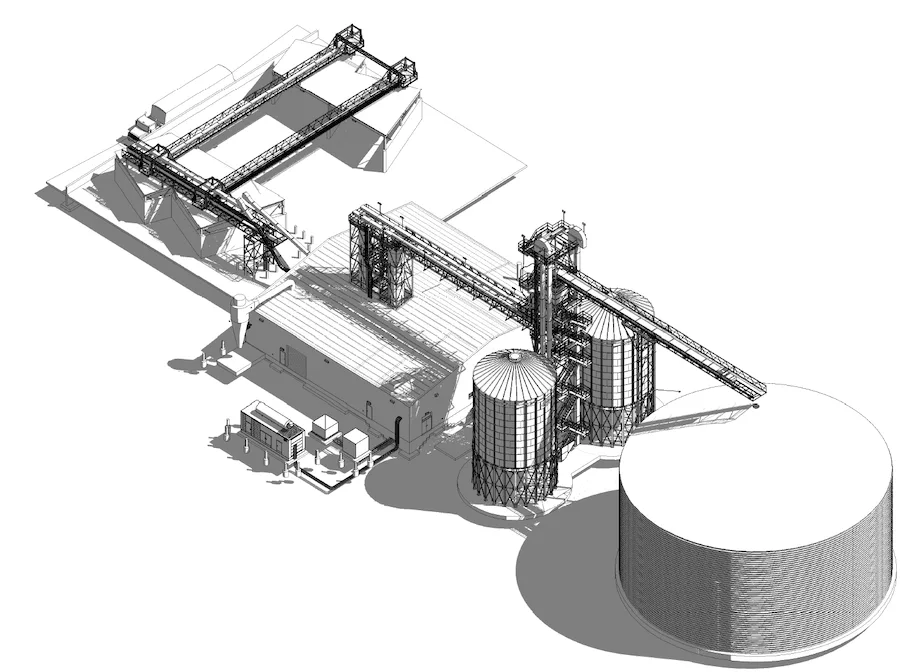

Grain Handling Inc., a division of AgriNorthwest, is adding a new commercial steam corn flaker to its operation in Plymouth, south of Kennewick. It will be the largest commercial corn flaker in the Columbia Basin, an AgriNorthwest official said.

Courtesy AgriNorthwestSeptember 12, 2024

It sounds like something Cornelius “Corny” Rooster or Tony the Tiger might dream up.

But, despite its name, the new piece of machinery being added to Grain Handling Inc.’s operation in Plymouth has nothing to do with the famous mascots or the cereal they hock.

Instead, the commercial steam corn flaker will be used to make feed that’s easier for cattle to digest. It’ll have the capacity to make 800 tons of flaked corn a day, supplying dairies and feedlots throughout the Columbia Basin, Yakima Valley and beyond.

“We are eager for this project to be completed. We’ve been planning this new facility for some time now, and we’re excited to bring this product to customers in the area,” said Devin Lybbert, director of marketing for AgriNorthwest, in a statement.

Grain Handling Inc. is a division of the Kennewick-based AgriNorthwest. It’s been around since 1980, and it operates a commercial grain elevator in Plymouth, south of Kennewick.

The grain elevator is next to the BNSF Railway mainline, and a rail loop was added there a little over 20 years ago, which helped the facility qualify as an approved shuttle loader and unloader, according to information from AgriNorthwest.

Seven people work at the Plymouth site full time, and two more positions will be added because of the corn flaker, Lybbert told the Tri-Cities Area Journal of Business.

Bouten Construction in Richland is building the corn flaker plant and already has broken ground. A project price tag wasn’t disclosed; the plant is expected to be operating by April.

Lybbert said it will be the largest commercial corn flaker in the Columbia Basin, with the site covering about an acre.

Brandon Potts, Bouten vice president, said he’s enjoyed the partnership with AgriNorthwest and Grain Handling Inc.

“Agribusiness means so much to our community here in the Tri-Cities, so being part of the design and construction of this unique facility is especially meaningful for us,” he said in a statement.

Steam corn flaking involves amping up the moisture in whole kernels of corn and then smashing them flat. The flaking process makes the starch in the corn easier for animals to digest, and it means more of the corn can be converted to energy for growth or lactation, according to information from AgriNorthwest. Less greenhouse gas is produced per animal, it said.

Latest News Real Estate & Construction Agriculture Manufacturing

KEYWORDS September 2024

Related Articles

Related Products